A broad range of standard, custom and specialized biodegradable polymers for medical applications

RESOMER® biodegradable polymers for medical devices such as orthopedics, spine, dental, cardiovascular and wound healing applications

RESOMER® is the world’s leading portfolio of many standard, custom and specialized biodegradable polymers. The breadth and versatility of our portfolio enables us to match the properties and characteristics of our biodegradable polymers to address specific medical device application requirements. The RESOMER® portfolio has strong record for safety, biocompatibility, supply security and quality across more than 30 years of commercial use. Our reputation as industry innovators continues with the recent launch of different biodegradable polymers used for medical textile applications, PLA-PEGs that combine strength with rapid degradation and osteoconductive composites for bone fixation devices. We are also the world’s first supplier with a full portfolio of medical grade powder, granule and filament-based biodegradable polymers for 3D printing medical applications.

RESOMER® portfolio of excipients for parenteral controlled release

The RESOMER® portfolio represents the industry’s leading selection of functional excipients for parenteral controlled release.

RESOMER® is the world’s leading brand for standard and custom biodegradable polymers used with implantable medical device applications

The RESOMER® portfolio of standard and custom biodegradable polymers includes a large, versatile selection of polymer families and compositions. Our

- Lactide,

- Lactide-PEG,

- Caprolactone,

- Dioxanone,

- Glycolide or

- Composite

-based biodegradable polymers can cover a wide range of medical device applications. Each of these RESOMER® products feature precise strength, elasticity and other mechanical and chemical properties, with degradation ranges ranging from just a month to more than four years.

If adjustable customization is required for a target medical device application, our best-in-class RESOMER® Select portfolio of biodegradable polymers can be easily tailored at full potential to address your specific needs. All RESOMER® Select products can be made to order via tunable characteristics including

- monomers,

- monomer ratios,

- polymer architecture,

- end groups and

- inherent viscosities.

Additional customizations can also be made to provide our biodegradable polymers in forms such as filaments, powders, tubes or granules.

Looking for information compiled in one document? Our brochures offer an overview of relevant details in just a few pages.

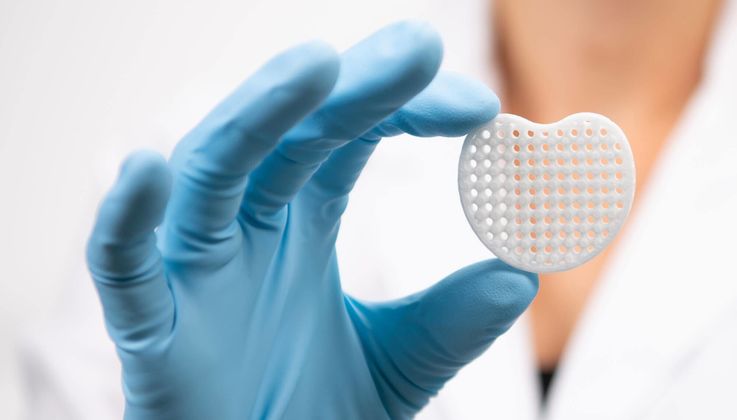

RESOMER® biodegradable composite polymers with osteoconductivity for bone fixation medical device applications

Evonik has developed an innovative platform of RESOMER® biodegradable polymer composites to enhance the performance of medical applications such as suture anchors, interference screws and dental devices. Years of research show that such bone fixation devices can strongly benefit from the osteoconductive properties of calcium phosphate-based additives included in all RESOMER® Composite grades for faster patient healing and recovery. Available standard medical grade products include

- a Poly (L-lactide) with 25 % hydroxyapatite additive and

- a Poly(L-co-D,L-lactide) with 30 % ß-tricalcium phosphate additive

with degradation times from two to more than three years. Customized RESOMER® Composite Select can also be tailor made to address specific medical device properties by varying additive type, concentration and particle size.

RESOMER® biodegradable polymers for textile-based medical device applications

Evonik has partnered with ITV Denkendorf Produktservice GmbH (iTVP) to create an innovative line of RESOMER® biodegradable polymers for use with textile-based medical applications used in wound healing including mono and multifilament yarns, sutures, meshes, tables and foils. These

- homopolymer (PGA),

- copolymer (PGLA), and

- block copolymer (PGA-CL and PGA-TMC)

-based biodegradable polymers are available in standard and custom compositions in a semi-crystalline form and optimized for easy processing into monofilaments or multi-filaments. Available in colorless and violet grades, they can be configured to precisely degrade from periods of less than four weeks to two months or more.

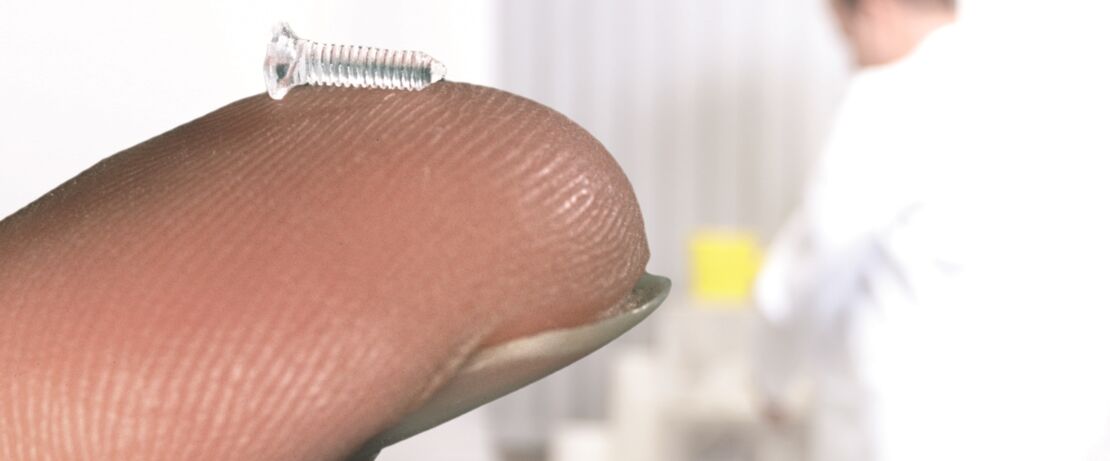

Biodegradable polymers for the 3D printing of medical device applications

Evonik has created the world’s most complete GMP portfolio of medical grade biodegradable polymers for use with all common 3D printing technologies used with implantable medical device applications.

- RESOMER® Filaments feature tight specifications for high resolution printing on Fused Filament Fabrication (FFF) equipment.

- RESOMER® PrintPowder is a range of free-flowing powders that are optimized for high resolution printing on Selective Laser Sintering (SLS) equipment.

These two 3D printing platforms of biodegradable polymers are ideal for use where medical applications require high compressive strength or complex geometries. Additional RESOMER® biodegradable options for 3D printing applications include granules for use with freeformer and bioplotter technologies. A range of related 3D printing services to support the testing and scale-up of your medical applications can also be provided together with our biodegradable polymers.